• Widely used for industrial oil from chemical plants, machineries, turbines etc;

• Portable oil purifier for removing particles from used/unqualified oil;

• Cooperation with international&domestic reputed brands;

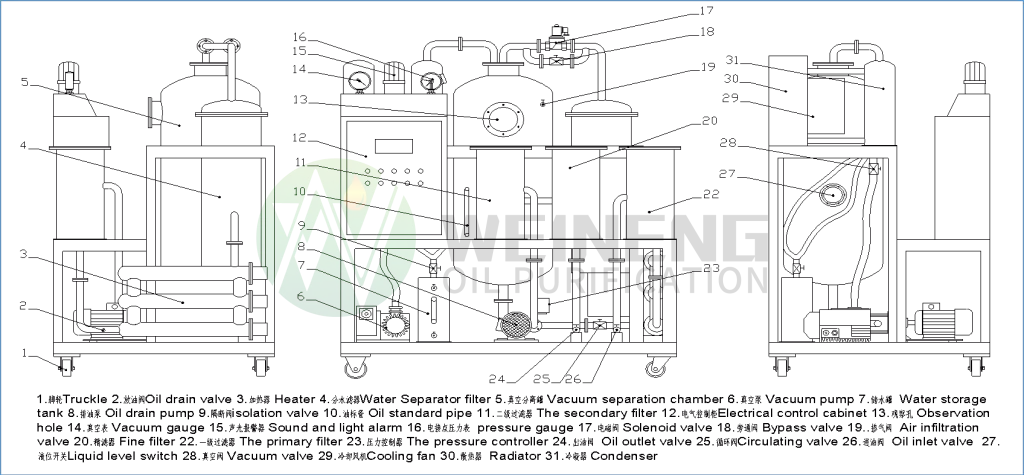

• Automatic control system, equipped with comprehensive protection mechanism;

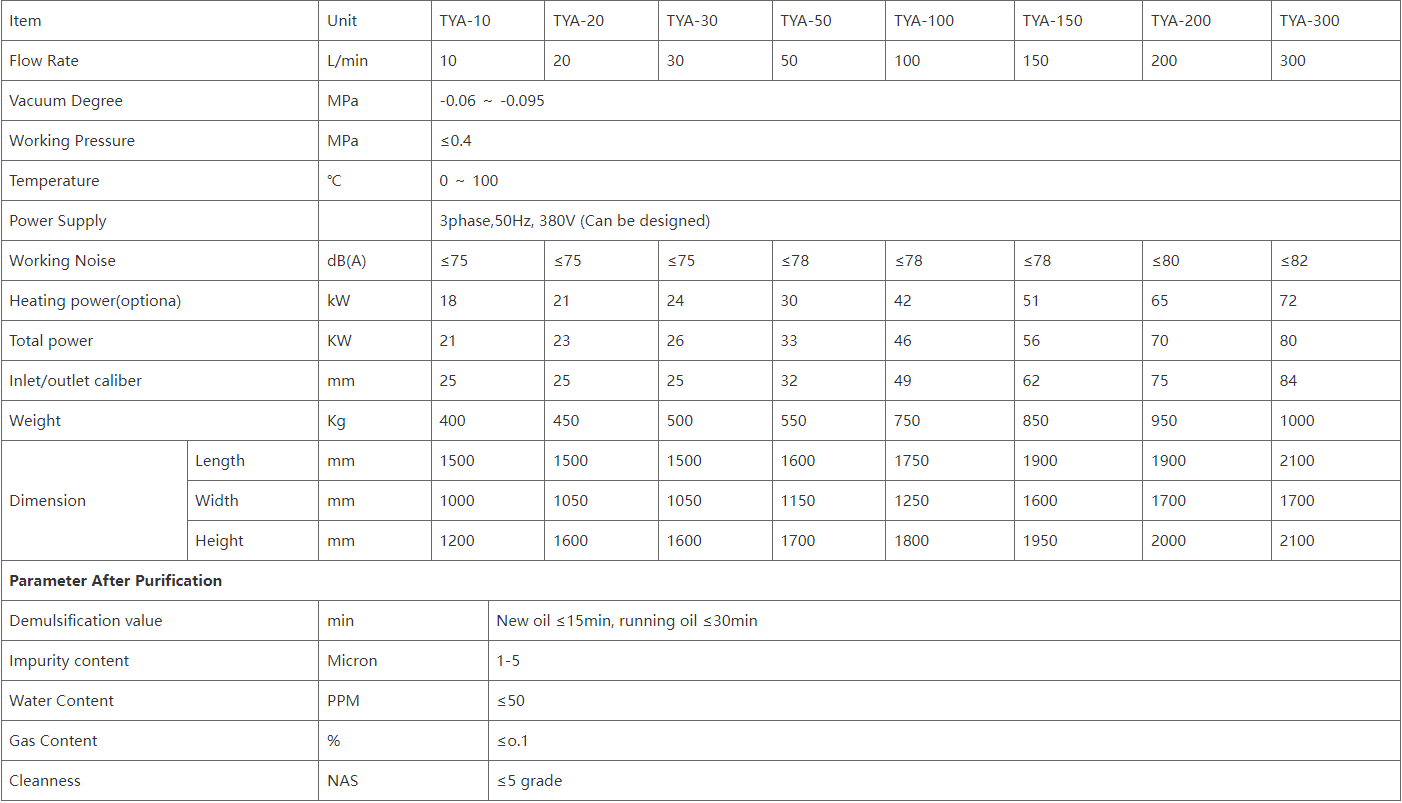

• Flow rate 600LPH to 30000LPH or as requested;

• 13 Years of purifier manufacturing experience;

• Customized fow rate, power supply, machine color etc;

• Explosion proof mode, coalescense seperation filters available for visible moisture;

• 2 years warranty, 7*24 hours technical support and after services.